|

|

Post by Dave Homewood on Jan 1, 2016 14:50:17 GMT 12

Here's another great update from Denys Jones... Thanks Denys! Hi Dave, Happy New Year to your good self. I've been concerned about the lack of postings of late and want to be sure that people know things are still happening preservation-wise at this time of year and also to gladden the heart of a Hudsonphile.  Following on from the Oct 18 posting things have been continuing in respect of the flap cabling systems on 2035. There's a bit of long ago history goes here... One day yonks ago a guy called into Don Subritzky's and asked "can you use Hudson parts?" Don of course said no but said that he knew someone who could, namely me. The chap vanished and returned a few hours later with numerous cartons of cables and other aircraft bits. Subsequently by way of Geo H Scales Ltd (a subsidiary of Scales Corporation who I was the national systems manager of) and their relationship with Malaysia International Shipping Corporation Berhad they migrated from AKL to CHC. They turned out to be pretty close to what we were told of their origin. Namely that the donor's father had stripped numerous parts out of three Hudsons intending to find a use for them one day. So there were heaps of properly coiled up cables and other related items all greased and otherwise protected and having been properly removed from the aircraft.. For the most part what we had been told about three a/c was borne out by items being there three times over. However in some cases there were more and in other less than there would have been from three a/c. As some of the cables had metal tags on them with Lockheed part numbers stamped on them we'd assume they were from a spares holding. So in recent weeks these stocks have been drawn on following the installation of the flap ram, as previously reported, to prepare for the outfitting of the flap bays. Now the technical part! There are 5 flap tracks on the Hudson and so the flap retraction and extension circuits have to be split out to each of them. Lockheed did this by way of a cable for each function going out to each flap bay where at each flap track 2 they split the cable into four. Three parts of this went to tracks 1, 2, and 3 while the fourth then carried on to track 4 where it split in half for tracks 4 and 5. At each track the cables run down to pulleys beyond the trailing edge of the wing and attach to brackets on the flap itself. Unbelievably in the bits acquired all those years ago we have numerous of both 4-way and 2-way cable split units so we have no problems meeting the requirement of four of each for the aircraft. The entire installation in the aircraft comes in at 29 cables of three sizes (5/32, 3/32, and 1/16 inch) and 17 different lengths. We also have heaps of original cables and turnbuckles etc. Out of the 29 cables we need, we have only 7 missing at this stage. All of these have then required degreasing and general cleaning up and attached is a pic showing a "before and after" of 4-way split units. Now I have to move onto the pulleys that they relate to and also the painting of the flap bays before installing them. hope this is of interest. regards Denys  |

|

|

|

Post by baz62 on Jan 1, 2016 15:17:38 GMT 12

Looks like you are going to have a fun job finding where all those cables go then rigging them although you'll probably wait til you have room to put the wings on and then worry about the flaps? Isn't it amazing what turns up?

|

|

|

|

Post by Dave Homewood on Jan 1, 2016 20:50:55 GMT 12

As a measure of keeping everything together in the one easy to find thread, Denys and I have decided to merge the older Ferrymead "Hudson Progress" thread in with the "Ferrymead News" thread. From now on all Ferrymead project news and updates can go into this thread.

|

|

|

|

Post by John L on Jan 6, 2016 14:40:40 GMT 12

Looks like you are going to have a fun job finding where all those cables go then rigging them although you'll probably wait til you have room to put the wings on and then worry about the flaps? Isn't it amazing what turns up? Amazing - and rather marvelous that a restored aircraft - even as a static display, is just that bit more "complete" |

|

|

|

Post by agile on Feb 6, 2016 17:34:35 GMT 12

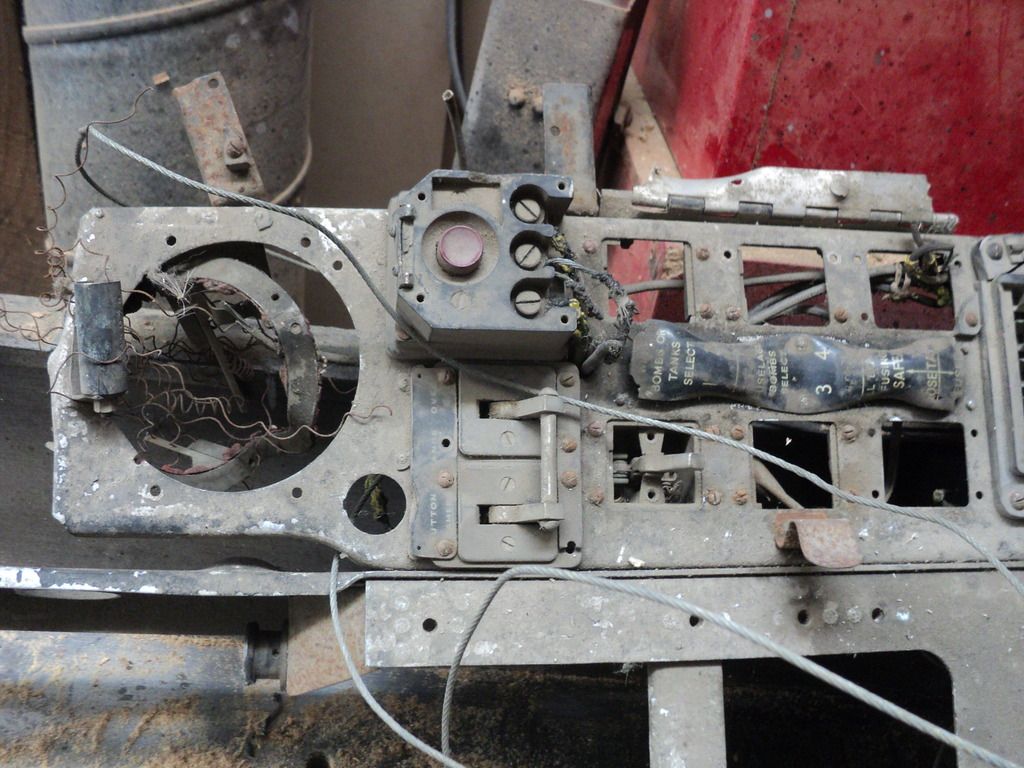

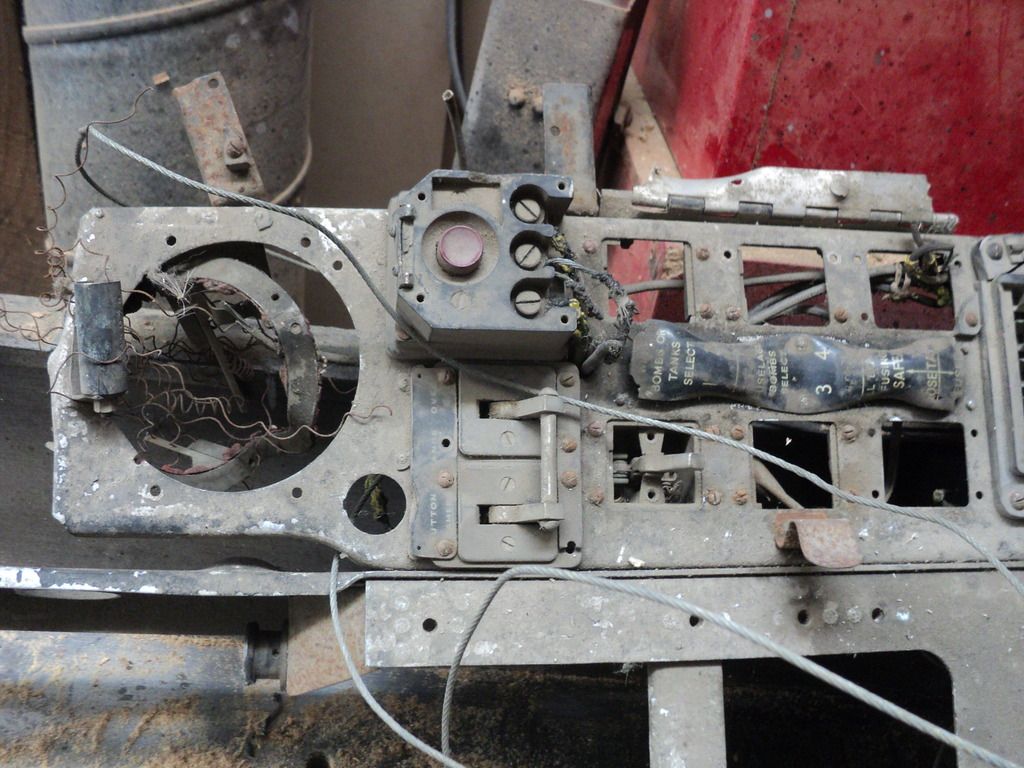

Another month, and more steady progress on all fronts. The quiet achievers down in the helicopter section have made some leaps forward this month on the Hiller UH-12E, ZK-HIK. This machine is being donated as parts become available by Wayne Van der Laan of Helicopter Management Ltd in Te Awamutu. This month has seen the engine frame and crankcase, and main rotor transmission reinstalled after stripping and repainting:  The guys are doing a really first class job with this machine - it is hard to do their attention to detail justice, especially with my crappy phone camera:  They are also mking gradual progress on the Hughes 300, again as parts become available. Recently the transmission was installed:  The local helicopter operators and maintainers, in particular Heli Maintenance Ltd have been very generous in finding parts for this project. While airframe repairs continue on the mossie, in the background other bits and pieces are slowly being tidied up. This is the centre cockpit panel, which includes the aileron trim control, the glycol pump for windscreen deicing, and on the right the bomb selector switches:  ***Edit A few before pics of the panel ***    Incidentally, we are missing the knurled knob off the top of the glycol pump, if anyone has a spare lying around.... Eventually this will replace the bare, corroded one that is currently in the machine. While talking of cockpit fitout it would be rude not to acknowledge Rob Brittenden, who has been very helpful in sourcing some of our cockpit fit. Rob is building a very ambitious high fidelity mossie simulator and in the process has gained an encyclopedic knowledge of FB-VI cockpits. Sometimes the little things take the longest time. We are missing a lot of the rubber blocks that support the hydraulic and other pipelines within the fuselage. These were originally cast rubber, but in the relativley small numbers we need it is more economic to cut them out of rubber sheet. Once I have the basic shape cut, I make the slots for the pipes using hollow drills, and my handy template (one for each part number):  The time consuming part is clearing the rubber out of the hollow drills after each part. The finished product is a satisfactory facsimile of the original:  One down, another 5 of these and 4 of a similar part to go... for now. |

|

|

|

Post by avro683 on Feb 7, 2016 12:31:28 GMT 12

Brilliant job on the repairs to the Mossie gent's!

|

|

|

|

Post by Dave Homewood on Feb 21, 2016 7:32:17 GMT 12

Here's the latest update from Denys: Hi Dave, Just to keep guys like and Baz :-P up to speed here's a shot of progress on Hudson front. Again a bit of history goes with what I've been doing. The starboard centre section was dug out of a farm cess pool at Dunback, Central Otago, and was somewhat reduced in size shall we say. So we have to add the flap bay areas using ribs from the flap bays off a spare outer wing we had. However the apertures for the cables as per my last report differ as you travel outboard so I've had to make up doubler plates for either side of the ribs and then cut out the corresponding apertures in the recycled ribs. Luckily the port centre section had the ribs in situ (it was retrieved from under trees rather than out of a cess pool!) so provided the templates for the doubler plates. ttfn  |

|

|

|

Post by agile on Apr 12, 2016 21:08:06 GMT 12

Well, it's been a couple of months, but we haven't been idle. Denys has been working hard on getting the F-27 back onto its feet. This first involved cleaning 30 years worth of crap off the nose bulkhead. The paintwork was in surprisingly good nick underneath, with just one area requiring a touch up. Here Denys is masking the offending area:  Once the painting was done, the nose leg went in - the first time in many years that BXG has had a proper nose leg.  Some fettling was/is required to mate F27-500 gear components to a -100, but we'll get there. I have been spending my time between cleaning the grease and oil out of the centre-section and removing a few small areas of alloy corrosion, in preparation for the c/s going back onto the fuselage. On the mossie front, work has moved forward to the cockpit area, which will be the most difficult repair on the fuselage. Here the ply has been stripped back, and new timber spliced into rotten solid members. In this picture you can see the contrast between new material and original:  Over the wing the solid member forming the interface between the fuselage and the upper surface of the wing has almost completely rotted away on one side, and was seriously fragile on the other:  Two new members were made using the survivor as a pattern:  The first went back in on Saturday:  The member goes back quite a distance aft of the wing, so to avoid having to unnecessairly dig into intact fuselage the new is feathered into the old:  The balsa and inner skin will have to wait until we drop the wing-centre section out, which in turn will have to wait until the cockpit area has been repaired to a state where it is strong enough to withstand the loss of the c/s. I'll try to get a shot of the finished repair in the next week or two! |

|

|

|

Post by Deleted on Apr 13, 2016 10:11:21 GMT 12

I'm shaking my head in awe of the Mossie team's skill. Amazing work.

|

|

|

|

Post by agile on May 14, 2016 19:38:54 GMT 12

Another month, another $0.65. Denys continues to chase the F-27 along. Today saw the installation of battery boxes on the forward bulkhead:  Like a lot of the bits we have, the boxes don't quite appear to match the aircraft, and require some careful fettling to fit. Also, what a mongrel arrangement of hardware is present in these aircraft - BA (including 1BA - WTH?) and BSF bolts, AGS and AN pipe fittings sitting cheerfully side by side. They must have been a barsteward to maintain, especially in their latter years. In my non-Mossie moments I have been slowly chipping away at the centre section, cleaning away years of grease and crap, removing alloy corrosion and priming ready for a repaint:  In Mossie-land the struggle goes on. Here project leader Dag begins removing the rotten ply from the lower half of the fuselage. How did we ever cope before the invention of the renovator - the Mossie project's favourite tool:

The lower nose currently looks a bit naked, but there is good progress on the upper:

A lot of repairs on the Mossie proceed like the song about the old woman who swallowed the fly. In order to mate the lower nose repair into the bulkhead at the forward end of the cannon bay we need to remove the section of the fuselage jig carrying this bulkhead. Before we do this we want to ensure that the cannon blast tube panel and surrounding structure is strong enough for us to trestle onto it. Removing this panel involved drilling out umpteen corroded flathead 2BA screws, to reveal:

The local rats have clearly used it as an HQ at some point in the past. The panel is in none too pretty a state as well:

Once de-ratted the bay doesn't look *too* bad.

On a more positive note the machine gun doors are more or less complete:

And Jordyn, our tame aircraft engineeering apprentice is making great strides in de-corroding the aluminium control surfaces. Here he models the latest fashion in ripped overalls:

Yay, more corrosion:

Here's one he prepared earlier. This has been fully de-skinned and re-riveted. The outer skin just needs a light sand and a repaint:  Inside the fuselage we have removed the aerial mast and refuelling port - this involved yet more contortions on my part in order to lie through bulkhead #3 on the upper surface of the wing looking up at the bolts:

The ply ring inside the fueslage was rotted beyond repair, and the underlying inner skin is a bit shagged too, but given the state of the outer skin we'll have to live with it:  I took the opportunity to give the immediate area of the port a quick sand and a paint before glueing in the new mounting ring:  In a quiet moment Dag also found time to repair the broken cockpit instrument panel:  ***Edit. And a before pic ***  We pretty much have a complete set of instruments for the Mossie, except for the boost and radiator temp gauges and the Mk VIII oxygen regulator (anyone got these lying around?). Likewise, if anyone has any AGS hardware or plumbing, or heaven forfend an RR Dart prop these would be gratefully received (and we have some parts and instruments available for swaps). Finally, another great story for this month, here is Tim, our youngest volunteer (he is in Year 10 at school) with the Allison C20 he has restored under the supervision of Paul in the Helicopter Section.

It is really great to see the commitment some of our younger volunteers are showing. |

|

|

|

Post by Dave Homewood on May 14, 2016 20:04:49 GMT 12

Great stuff!

And well done Tim!!!

|

|

|

|

Post by davidd on May 15, 2016 10:58:13 GMT 12

Yes, I totally agree, great shots of some heroic work being undertaken.

Dave D

|

|

|

|

Post by Deleted on May 15, 2016 17:32:40 GMT 12

More great work on display, and bravo Tim!

|

|

|

|

Post by baz62 on May 15, 2016 17:40:10 GMT 12

Great work lads. Old Dags he's worth his weight in gold. Wonder if he would notice if a set of Auster flaps went through the corrosion removal line..........its about time I paid another visit, Anthony has been in hospital and once he's fighting fit again the "Auster thieves......I mean "Auster lads" will make an appearance.

|

|

|

|

Post by agile on May 15, 2016 21:07:37 GMT 12

Thanks Baz. How about if you can 'find' a set of intact Mossie wing spars for us we'll sort your flaps.  No? Seriously, always happy to see you blokes, and I must drop Ants a line and see how he's doing. Cheers A |

|

|

|

Post by agalbraith on May 18, 2016 11:19:10 GMT 12

Great update guys! Thanks for asking after me, I appreciate it. Long story short, gallbladder removal Sat arvo and home Monday arvo, still very sore but got some good drugs to get me through.

Den is a machine with what he achieves, British, American or Dutch airframes, he can do em all! Tim, and Jordyn are doing great as well, nice to see young people involved and not just talking about it. Of course Dag, Alex, Dave, Paul etc..... this place wouldn't be what it is today without their dedication.

Look forward to getting down to the workshop again soon boys!

Alex, I have replied you about a couple of things..

Cheers

Ants

|

|

|

|

Post by Dave Homewood on May 18, 2016 14:14:58 GMT 12

Does that mean you're now just Anthony Braith?

I hope you get back to your old self soon mate!!

|

|

|

|

Post by Deleted on May 18, 2016 16:08:45 GMT 12

Dave, I see what you did there!

Good on you Anthony, so glad to hear you're well!

|

|

|

|

Post by agile on May 18, 2016 20:36:31 GMT 12

Does that mean you're now just Anthony Braith? Nice!   |

|

|

|

Post by agile on May 18, 2016 20:41:19 GMT 12

Alex, I have replied you about a couple of things.. Received and briefly responded. Thanks mate, and get well soon! Cheers A |

|

No? Seriously, always happy to see you blokes, and I must drop Ants a line and see how he's doing.

No? Seriously, always happy to see you blokes, and I must drop Ants a line and see how he's doing.