|

|

Post by starr on Jun 26, 2016 17:22:26 GMT 12

Wasn't a Mini Moke used by the DC3 crew, it was a Mini Minor.

|

|

|

|

Post by Dave Homewood on Jun 26, 2016 17:49:34 GMT 12

Oh. What's a Mini Minor??

|

|

|

|

Post by Dave Homewood on Jun 26, 2016 17:50:36 GMT 12

Ha, looked it up. So a normal Mr Bean style Mini. Never knew that.

|

|

|

|

Post by agile on Jul 28, 2016 18:07:32 GMT 12

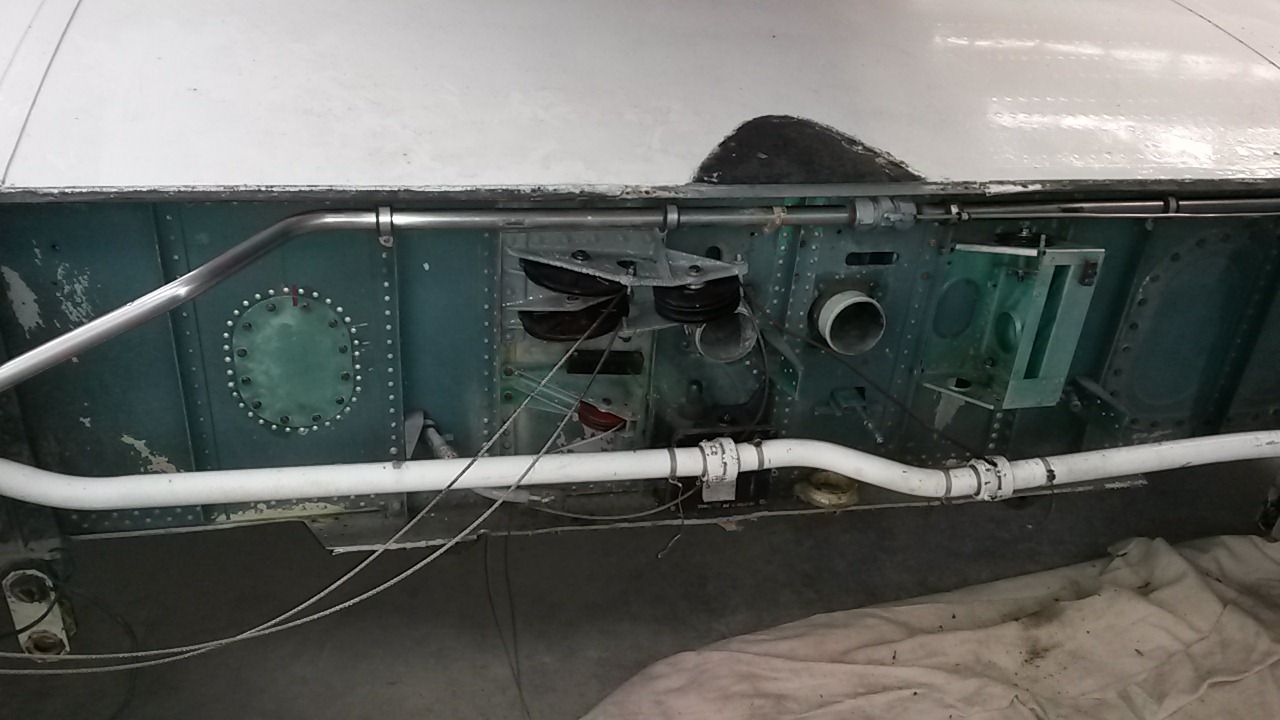

Things are always a bit slow in winter, when it is usually to cold to paint anything. Rapid visual progress on the Mossie has been stalled by getting the cannon blast tube panel repaired and put back in place. The panel has been de-riveted and corrosion treated, and we are now starting to reassemble it:  Another part that has taken a lot of work to repair was the air intake elbow for the second engine. At some point in its history the engine had been dropped on the elbow, distorting it somewhat:  Dag took 16(!) anneals and a crapload of patience to get it back to more or less the approved shape:  Here we are riveting the flange back on. As we don't have have a setting head for snap heads, hand-riveting is the order of the day:  Most of the easy ones done. Not bad for a beginner (if I do say so myself):  The cold isn't deterring volunteers, here Reed patiently scrapes 70 years of crap off some of the fiddly areas of engine #2:  and Tom finishes installing the feathering pump on engine #1:  The aforementioned feathering pump when it came off:  And before installation:  I have been doing a bit of a sort out of our project photos, and came across some 'before' shots, which I have pasted into the previous posts. |

|

|

|

Post by baz62 on Jul 30, 2016 15:20:37 GMT 12

Great update! Yes winter is a pain sometimes. I briefly thought about trying to do some painting on the Auster today but time and variable weather made it a no go. Anthony managed to do some last Monday and he now has a flare gun mount (thankfully NOT bloody green!) bolted into XHK's cockpit.  |

|

|

|

Post by Dave Homewood on Jul 30, 2016 16:48:24 GMT 12

Winter? When is that getting here?

|

|

|

|

Post by Richard Wesley on Aug 6, 2016 20:08:34 GMT 12

Thanks for the update photos, great that there is still progress in the middle of the cold months. I always enjoy the before and after photos, I'll have to check back now at some of your previous posts.

|

|

|

|

Post by Dave Homewood on Aug 14, 2016 0:37:27 GMT 12

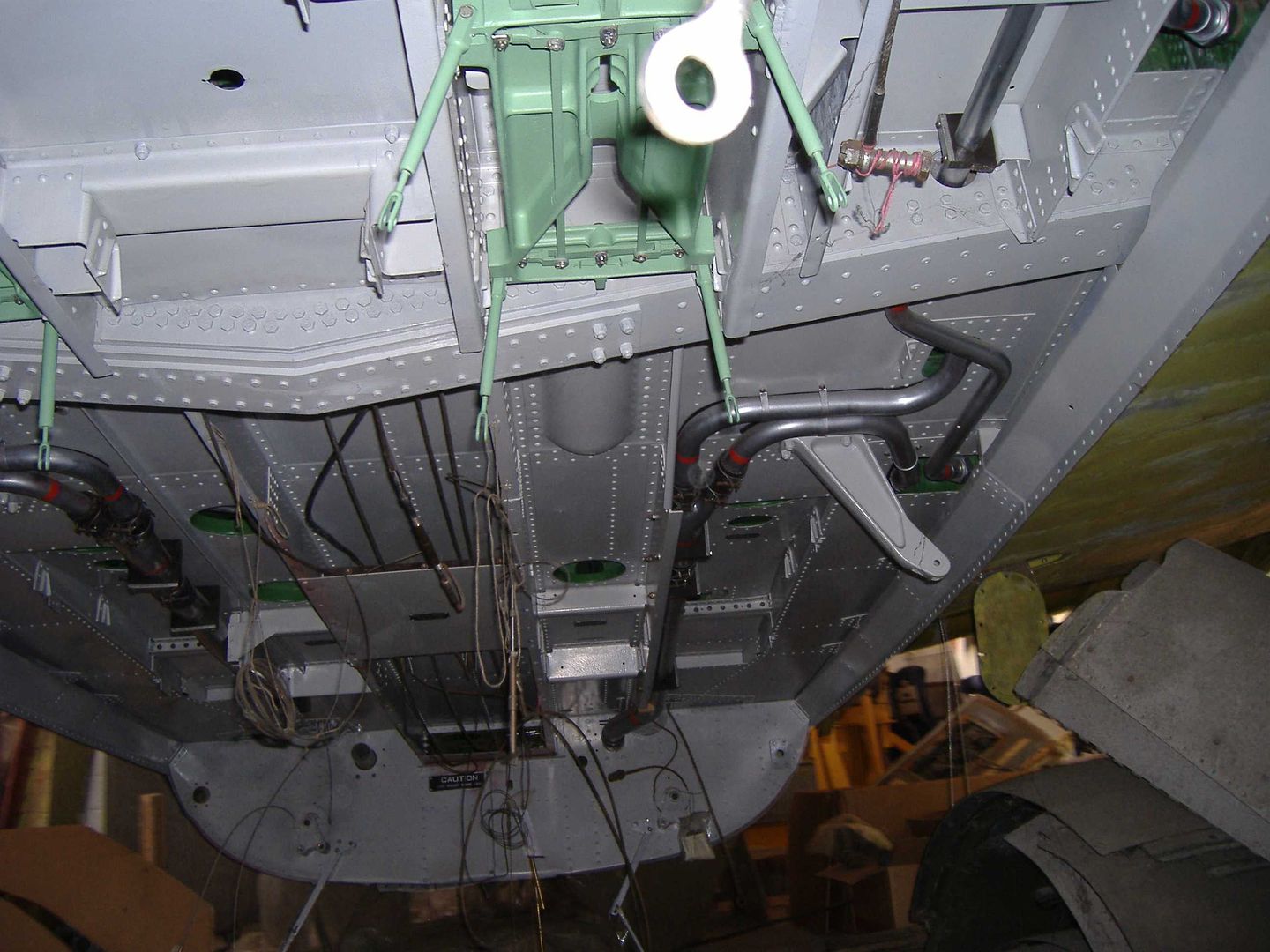

Here's the latest fantastic update from Denys!"Here's a couple of pix with a bit of a story you might like to share. The first shows the floor bay port side aft of the spar of the Hudson and forward of the bay where the flap ram as per Oct 18 2015. It's a busy wee area. Looking at the left side there is a square duct runs along the side which is part of the crew heat/aircon. Below it are two pipes which are fuel lines. The red line is Lockheed fuel id. The upper one is the fuel feed from the port aft fuel cell and runs fwd to the tank selector valve which is below the pilot. The other is the dump from the same cell and feeds to the dump aft of the bomb bay. The silver spring above the aircon duct is what actuates it and there will be a Bowden cable that comes down the side wall and joins it. The silver duct coming down the wall is afrom outside air and must have been to provide cooling for the units I'll describe in a few lines below. The hydraulic ram is the bomb door actuator and running alongside it are the lines leading to the flap ram and you can see them in the third image on the post of Oct18. A wee story about the ram is that yonks ago (1980's or so) one of our Ferrymead railway colleagues brought a work colleague of his from Dunedin, who was up here for the weekend, through our workshop and he saw 2035 and revealed that his family had a ram from a Hudson which then duly turned up and there it is! The other thing is the piping running through the spar in the upper part of the shots is the deicing ducting for the wing leading edges. Today that all got covered up with the floor panel that belongs there. Putting it in place has been delayed because it hosts the dynamotor, read power supply in modern computer based speak, called an MP10-G. Some years ago Charles Darby was instrumental in my getting one of these but we lacked the mounting for it (the silver bit in the second photo). We've been after it since but the MP10-G units were largely dispensed with when post war radio hams acquire radio kit as they simply replaced the units' power supplies with 203v units fro commercial sources and so had 3-pin plug operation. Recently Charles and I had email discourse on the matter and he donated some components for the base that he had and so I fabricated the rest and today it went in. Tucked in fwd of it is another rack mount. This is actually original NZ2035 and was part of the only substantive bit of floor left in the a/c when we got her. It is the mount for the IFF. I'm very very keen to get the unit that goes on that but they are very rare, even in the US the country of origin. They have various id's. Bendix who made then refer to them ad BC-966 but the USAAC and the USN each had different id for them and then again depending on them being 12v or 24v. So I'm after either and SCR-595(-A or -AZ variant) to use USAAC designations, or ABK (with or without a -1 at the end) to use USN's designation. Hope this is of the usual interest. regards, Denys"

|

|

|

|

Post by davidd on Aug 14, 2016 15:43:34 GMT 12

Great stuff Denys, really getting down to the nitty gritty here, getting right to the guts of the issue.

David D

|

|

|

|

Post by Dave Homewood on Sept 4, 2016 3:44:27 GMT 12

The latest from Denys: "Following on from the last thread post where I referred to the dump valve feed that runs back to through the bomb bay aft. Here's a photo of the bomb bay and you can see that line coming in from the right and doing a U-turn to head aft, after joining with the one from the fwd fuel cal and in the distance you can see the fee going through the aft wall of the bomb bay. As an aside you might like the view of the green object which is the mount for a bomb rack. They're a rather distinctive beastie and any leads on more of then would be most welcome. The second shot shows a small bay aft of that wall where that feed, and it's mate from the stbd side merge into the fuel dump which then hinges out through the under fuselage hatch to atmosphere. I've had to deal to this business as a precursor to something to be installed soon...watch this space with bated breath! ttfn"   |

|

|

|

Post by agile on Sept 5, 2016 22:14:19 GMT 12

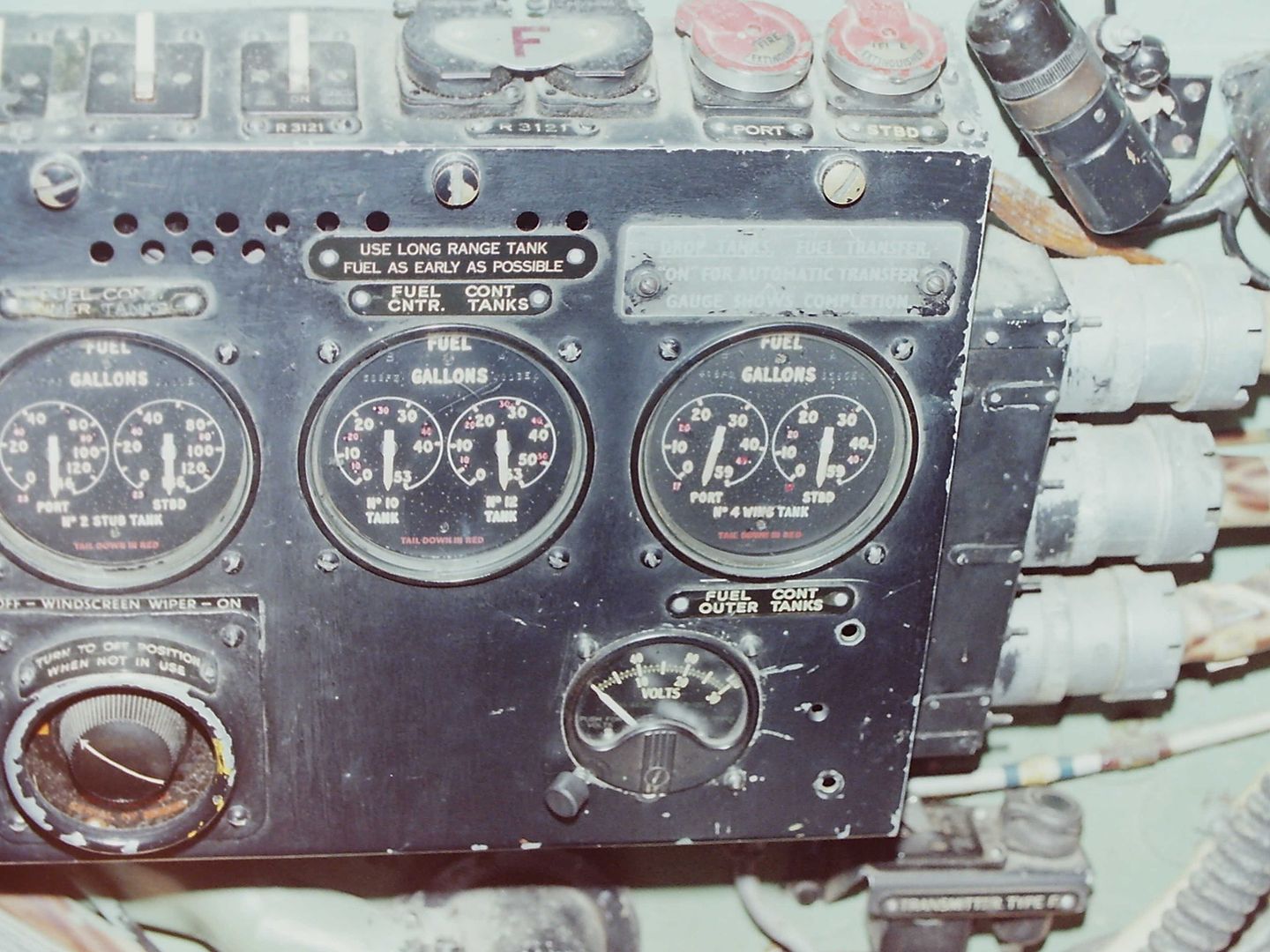

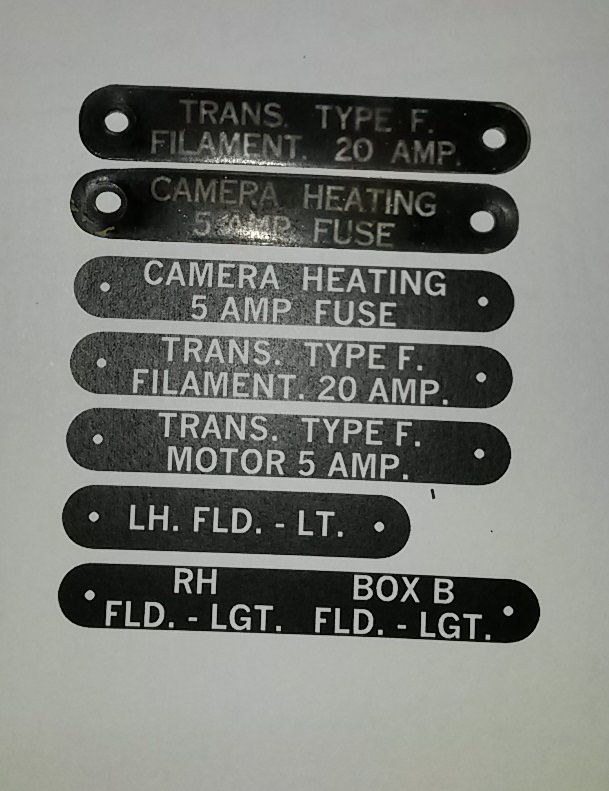

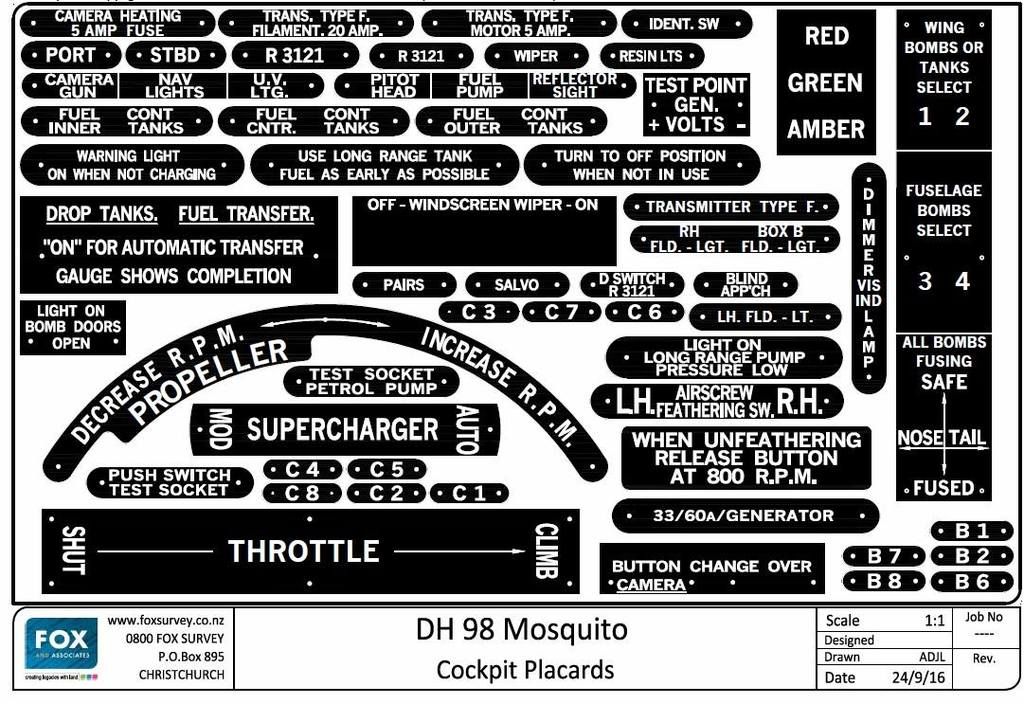

Meanwhile at the Mosquito end of the workshop, work on the cannon panel continues: Second to last blast tube goes in:  Interesting that in the area on the starboard aide where the panel had corroded through none of the holes in the stiffener lined up with the holes in the panel - the whole area must have been in considerable tension, which is no doubt why the corrosion was so bad. You can't beat British craftsmanship eh? Last blast tube in, and in the van ready to go back to Dagys for painting:  The near finished article, note that the break on the starboard side has now been glassed over:  Meanwhile Reed gets on with replacing the fittings on the forward armoured bulkhead, using Duralac kindly donated by Mr Galbraith of this parish.:  Jordyn continues his fine work on the ailerons:  The portside panel is pretty well complete bar instruments (looking for more of the lamp fittings like the one shown):  I don't have any pics but Box B on the starboard side is also coming along. This has led to a need to procure new placards for the cockpit. These were originally 'Decalomania' (I thought this was a modeller's disease but apparently not) applied to the reverse of strips of cellulose acetate that were then riveted or screwed to the panels. Here is an original Box B (not ours), with the cellulose labels below the fire/destruct switches and around the fuel gauges:  I have started drawing up replacements (in AutoCAD - not perhaps the first choice of graphic designers). A couple of originals at the top:  A local outfit has agreed to print them to celluloid (or some such) at a very reasonable rate. We will do a few sets, so if anyone wants some for their flight sim set up..... Another interesting item, we had some very corroded mainwheels in our store of bits. One hub in particular was so bad it basically vanished after a short visit to the acid bath. On the right is what it should look like:  I popped down to see what Denys was up to on his *other* project the other day. This is the rear of the F-27 centre section, which is coming up nicely:  |

|

|

|

Post by ErrolC on Sept 5, 2016 22:36:22 GMT 12

Meanwhile at the Mosquito end of the workshop, work on the cannon panel continues: ... I have started drawing up replacements (in AutoCAD - not perhaps the first choice of graphic designers). ... Ha! Not elegant, but you know it! Thanks for all the lovely detail. |

|

|

|

Post by agalbraith on Sept 6, 2016 15:26:18 GMT 12

Thanks for the updates guys! Brilliant work going on, on all fronts.

Alex, I think I have a couple of those lamp fittings NOS(shown in the pic of JBox 'B') for the Auster, if you could use them now I am happy to donate them and get me some more later on...

Be an excuse for me come out as well, I am sick of coughing up sanding dust from my floorboard refurb!

Cheers

Ants

|

|

|

|

Post by Deleted on Sept 6, 2016 16:00:37 GMT 12

The Mossie stuff is looking great! I'm very envious of those young guys getting to work on it. Thanks for sharing.

|

|

|

|

Post by agile on Sept 6, 2016 19:51:35 GMT 12

Thanks for the updates guys! Brilliant work going on, on all fronts. Alex, I think I have a couple of those lamp fittings NOS(shown in the pic of JBox 'B') for the Auster, if you could use them now I am happy to donate them and get me some more later on... Be an excuse for me come out as well, I am sick of coughing up sanding dust from my floorboard refurb! Cheers Ants Ants mate you're a gentleman and a scholar. Not sure that we would use them 'now' as we are still a wee way from building up the panel - your call if you can bear to part with them. The Mossie stuff is looking great! I'm very envious of those young guys getting to work on it. Thanks for sharing. You're welcome. It's all about geography - move to Christchurch and you're on the team.  |

|

|

|

Post by Dave Homewood on Sept 11, 2016 14:23:10 GMT 12

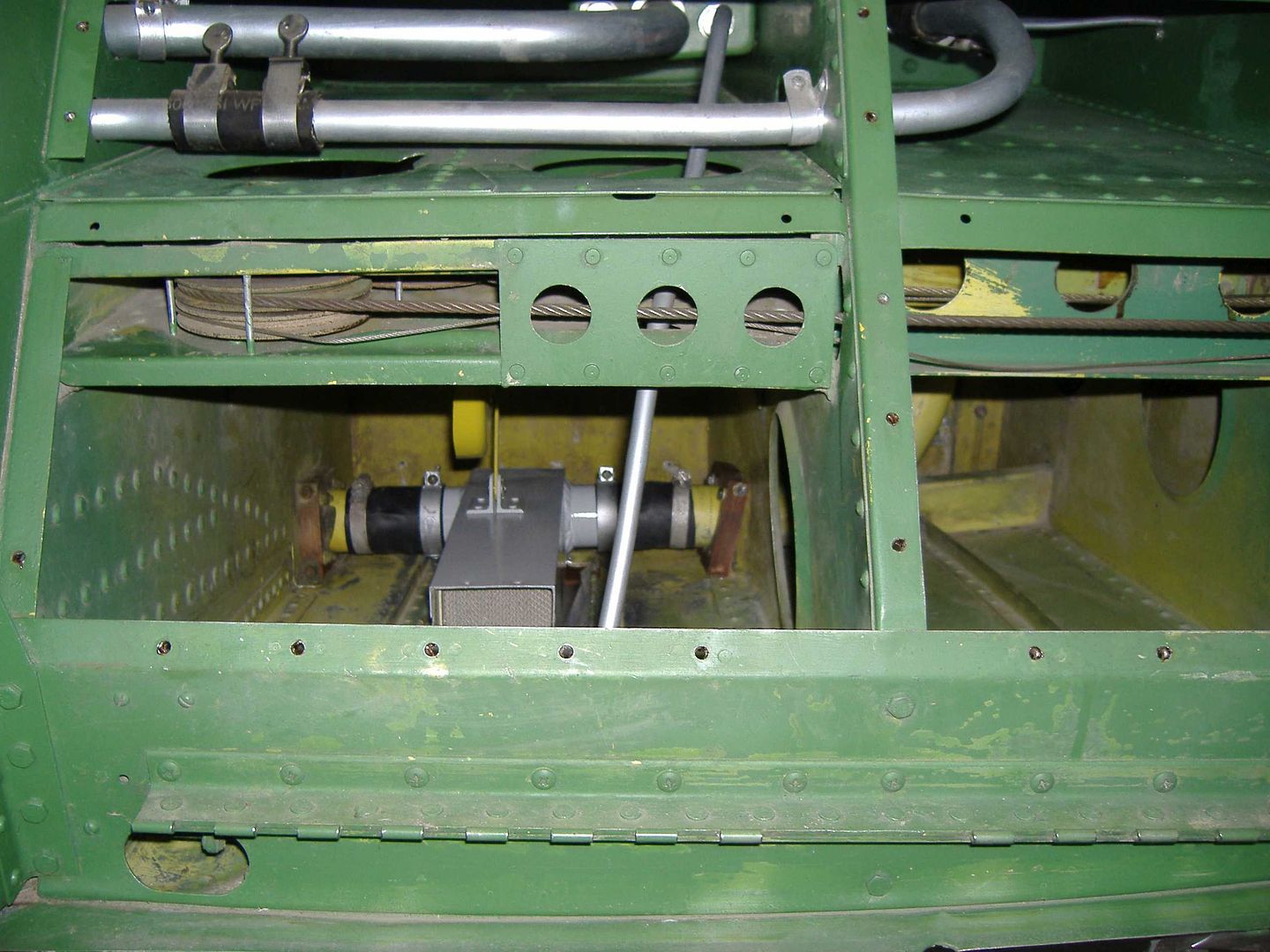

Here's the latest Lockheed Hudson update from Denys Jones: Hi Dave, Here's the story on why I told you wait with bated breath last week. The cavity where the dump outlet is lies under the floor of the main cabin and its cover plate forms the forward wall of the ventral gun position. It's a lot easier to work on it when you can kneel in the gun position and reach into it in relative comfort hence last week's activity because this week we re-installed the ventral gun bath, or in Lockheedspeak the tunnel gun position, as per the attached. The unit is fitted by offering it up from under the aircraft and is held in place by a piano hinge at the forward end and the rear end hangs on the two screw jacks you see mounted on the semi-bulkhead aft of it. The jacks are driven up and down by a chain drive from the hand crank unit to the left. Unfortunately this whole unit is inoperable due to the treatment it stood in its days on the farm. When we got 2035 the bath was hanging under the aircraft some 3-4 inches and was lashed up with some No. 8 wire. The a/c must have been dragged around a bit while it was like that as the whole bath is twisted but more importantly one of the two screw jacks was also bent. A local concern that specialises in making threaded materials made us a replacement but they couldn't match the original one's thread profile and pitch and so the two screws won't work together. So the bath is going to be held in the up position by the two jacks. As always hope this is to your interest. cheers Denys   |

|

|

|

Post by agile on Oct 9, 2016 18:30:10 GMT 12

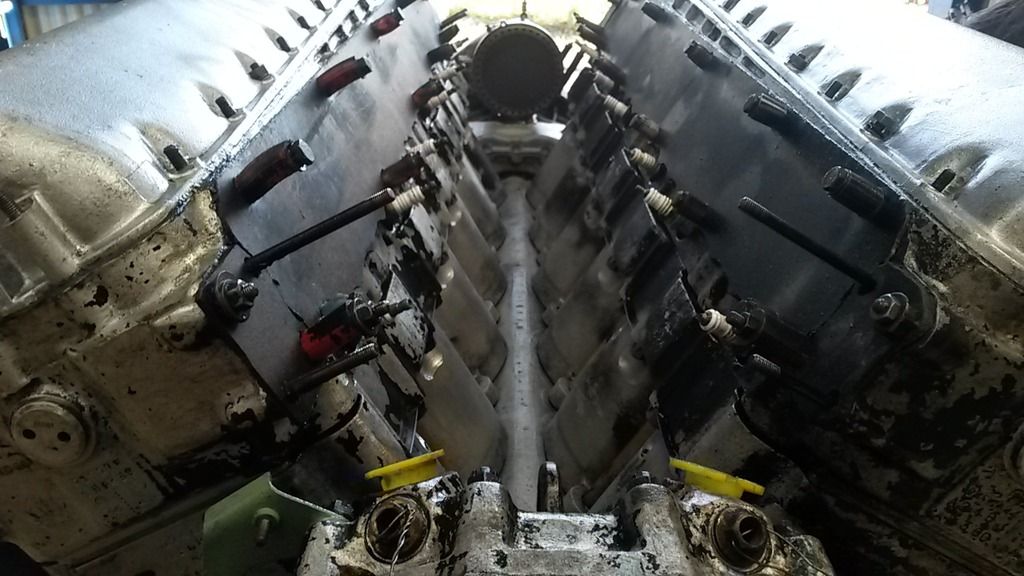

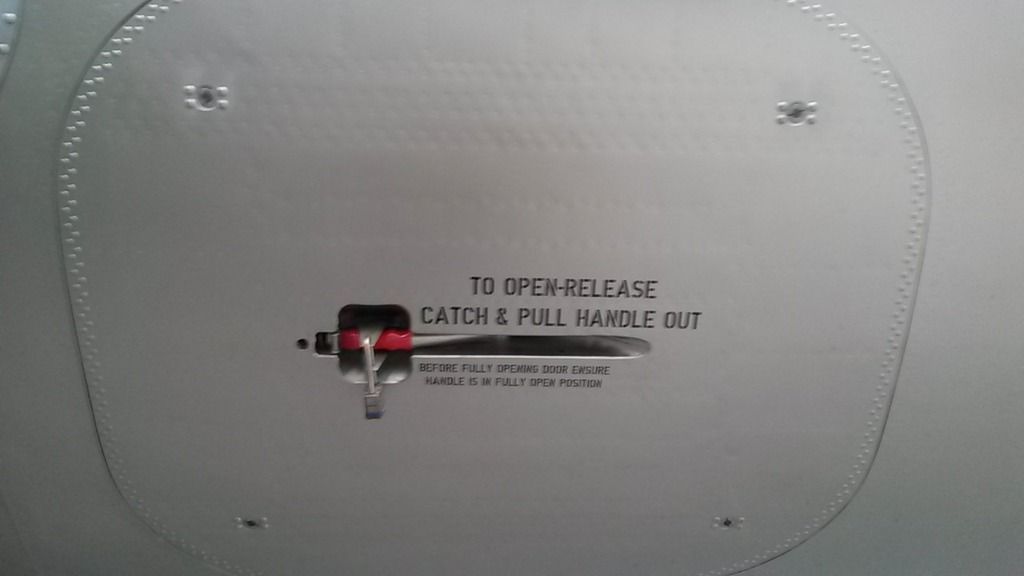

It's been a big month in the Mossie world, and while the buttered confectionary has to go to the chaps at Ardmore, we haven't been idle. Visitors to our workshop may remember our second RR Merlin, which until a year or so ago looked much as it did when it came out from behind the garage in Dunedin in the '70s:  Once Rodger (recently with help from Tom and Reed) got towards the end of the first engine, they began to take as many parts off the second as possible. The sump and rocker covers were removed and acid stripped, and the internals inspected for corrosion (none found, thankfully). As much of the grease and crap was scraped off as possible, and any openings were blanked off. A few weeks back the engine saw the light of day for the first time in 15 years, for a targeted sandblast and final clean. Here Tom is hard at work:  Nothing like a clean bank of cylinders:  Once this was completed the engine came back inside for priming and painting. Dagy did the honours....:  ...and the final result:  Now the nice thing about Ferrymead is that while there are 18 different societies, it's a very friendly place and you can always rely on the other groups to help with the heavy lifting. In this case our flange-wheel mates from the Canterbury Railway Society took time out of their day to lift the Merlin out of its bearers so they could be painted:  A week later, bearers painted, they downed tools again to lift it back in again (there weren't enough spare bods at our end for a photo). Now we have two shiny Merlins and the boys have a power of work ahead to reassemble number two:  While all this was going on Dagy and I found time to finish the cannon blast panel. The white tape was originally asbestos, but in this more careful age we decided nylon webbing would suffice:  Dagy has also been working on finishing our .303 ammo boxes. Dagy originally made the woodwork for 8 boxes, four of which are in KA114. Wal's boys made the metal work for all 8, and Dagy has now finished the final assembly (with the original in the foreground):  The trickiest part was riveting through wood - even the softest rivets would rather expand into the wood rather than countersink into aluminium. I have finished my cockpit placards - with thanks to my employers Fox & Associates, who are very generous in letting me use some of their resources (for example AutoCAD) for Ferrymead things.  Elsewhere Deny's attention to detail is evident in the new vinyl labels on the hold doors of the Viscount:  Denys has also installed one of the bombdoors of the Hudson, with help from new recruit Steve:  When not helping Denys, Steve and his lads have also been hard at work on cleaning up the main gear leg for the F-27:  Steve is a bit of a Mossie enthusiast (who isn't  ) and he has started a Facebook page here to celebrate all things Mossie, but which I will try to keep fed with the happenings from our particular wooden wonder. Lastly on Sunday 6 November we will be having a slightly aeronautically themed 'Steam Sunday' at the park. As the name suggests the steam train will be running, and at this stage we are hoping to have James McNutt's Fairchild-Hiller FH1100 fly in for the day (weather dependent), as well as workshop tours, and hopefully one or two other items of interest still being arranged. We look forward to seeing some of you there. Cheers A |

|

|

|

Post by Dave Homewood on Oct 9, 2016 23:14:51 GMT 12

Fantastic progress!

|

|

|

|

Post by suthg on Oct 10, 2016 8:12:47 GMT 12

Lovely pics!! It was great to visit there during summer this year! Some exciting views of progress then and even more now!! Well done.

Graeme

|

|

|

|

Post by agile on Nov 3, 2016 19:35:42 GMT 12

Just a heads up that we will be having the aeronautical themed Steam Sunday this weekend. As well as steam trains and trams there will be a display on life in the field in Antarctica with help from LC-47H 17221 and some real live Antarcticans, and weather permitting (looking good) Winged Hunters' Fairchild-Hiller FH1100 ZK-HCI will be flying in and will be on static display. We will also be running tours of the workshop so you can check out the latest progress on the Mossie, Hughes 300, Hiller UH-12, Sunderland and Hudson, and of course the Viscount. Gates open 10am, admission $30 Adults, $25 for students and seniors, $15 for school kids and under 5s free. A family day pass (two adults two kids) is $75. Come on down and meet the team - we look forward to seeing you there.

Cheers

A

|

|