|

|

Post by Deleted on Jan 2, 2022 15:27:07 GMT 12

Big smile on my face seeing the horizontal and vertical stabs pinned together like that!

|

|

|

|

Post by nzgrasshopper on Jan 7, 2022 22:25:05 GMT 12

A few sleepless nights have solved the problem. The last update shows the fin and horizontal stab positioned for the earlier models.

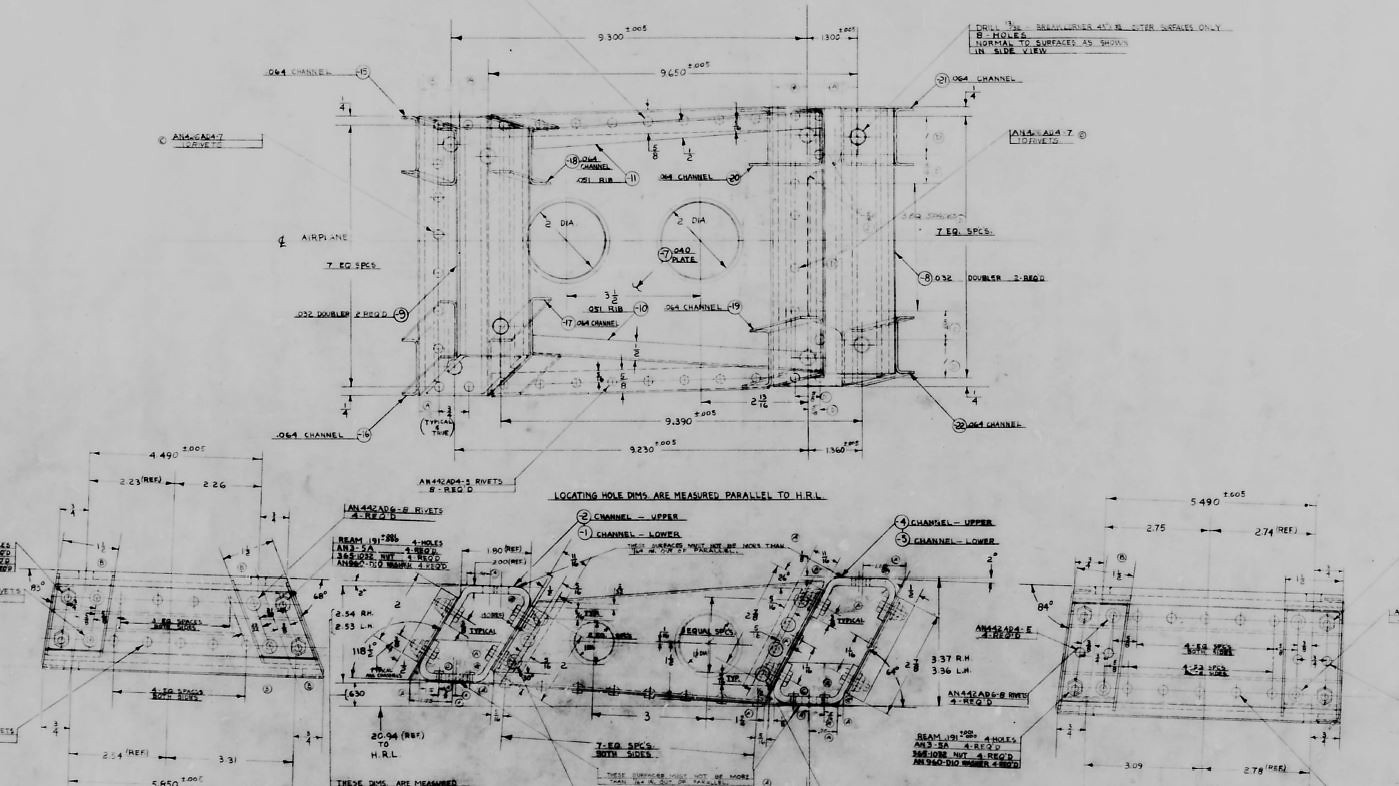

Finally tracked down the drawing for the junction box that sits under the forward section of the fin and connects to the rear of the horizontal stab. The back of the fin then straddles the raised fuselage extension from Sta #16 to #18.

Back home tomorrow and will post the drawing explaining this better.

|

|

|

|

Post by nzgrasshopper on Jan 8, 2022 21:37:59 GMT 12

Tomorrow's project.  |

|

|

|

Post by nzgrasshopper on Jan 10, 2022 0:29:57 GMT 12

Maybe more than a one day project.  |

|

|

|

Post by Deleted on Jan 10, 2022 6:45:07 GMT 12

*shakes head in amazement and admiration*

|

|

|

|

Post by nzgrasshopper on Jan 10, 2022 19:29:44 GMT 12

|

|

|

|

Post by Dave Homewood on Jan 10, 2022 19:48:26 GMT 12

That tail!  |

|

|

|

Post by Deleted on Jan 11, 2022 8:32:37 GMT 12

What Dave said!!!

|

|

|

|

Post by davidd on Jan 12, 2022 12:25:24 GMT 12

What that wascally wabbit is thinking!

|

|

|

|

Post by nzgrasshopper on Jan 26, 2022 10:54:32 GMT 12

Back home again. Nice surprise waiting for me. 3D printing is becoming way more accessible and producing better quality items. Just need to convince the procurement officer that a SnapMaker 2.0 is an essential item. Not sure if this will be fully functional, but it will have screws .etc used to install. Only issue is the arrows are in the same direction.  |

|

|

|

Post by Mustang51 on Jan 26, 2022 12:38:49 GMT 12

That's ok....good to confuse the enemy........

|

|

|

|

Post by baz62 on Jan 27, 2022 7:43:01 GMT 12

I'm squinting at the photo on my phone trying to decide what it is.....trim wheel? Yes 3D printing is a wonderful tool. Here at work one of the CAD designers built his own from a kit. It got used to print a complete Mazda rotary crankcase. We were making one for a client(as you can't buy new ones anymore) who builds race spec ones for the US market. We 3d printed it so he could basically assemble the engine and make sure the modifications made didn't interfere with anything.

|

|

|

|

Post by nzgrasshopper on Jan 27, 2022 8:27:46 GMT 12

I'm squinting at the photo on my phone trying to decide what it is.....trim wheel? Yes 3D printing is a wonderful tool. Here at work one of the CAD designers built his own from a kit. It got used to print a complete Mazda rotary crankcase. We were making one for a client(as you can't buy new ones anymore) who builds race spec ones for the US market. We 3d printed it so he could basically assemble the engine and make sure the modifications made didn't interfere with anything. Just as hard to read on the printed thing. Filler cap for the fuselage main fuel tank. The SnapMaker 2.0 is what I have my eye on. ![]()  |

|

|

|

Post by baz62 on Jan 28, 2022 16:25:37 GMT 12

Ah yeah, now I look at it on my PC it's more obvious. Wonder how long it will be before most of us have a 3D printer at home!

|

|

|

|

Post by Dave Homewood on Jan 28, 2022 17:04:04 GMT 12

I know a few people who do have them Baz.

|

|

|

|

Post by nzgrasshopper on Jan 28, 2022 22:08:58 GMT 12

All the bits for the horizontal stabiliser tips. The brass sections would normally have been a rolled section. Way to complicated for me, so the next best option is to make up the top and bottom skins and solder the curved leading edge.  |

|

|

|

Post by nzgrasshopper on Jan 29, 2022 18:48:29 GMT 12

|

|

|

|

Post by Dave Homewood on Jan 29, 2022 22:08:49 GMT 12

Very cool!

|

|

|

|

Post by Mustang51 on Jan 29, 2022 23:37:43 GMT 12

Bloody brilliant !

|

|

|

|

Post by nzgrasshopper on Feb 1, 2022 17:42:11 GMT 12

The laborious task of drilling out, countersinking and riveting the skin stiffeners prior to riveting the skins onto the webs.   |

|